Deburring Technologies - Part I

Deburring Basics

Grind Master Machines Pvt Ltd has worked on deburring applications for more than 35 years thereby gaining expertise in deburring processes.

Authentic information on deburring is not readily available and often misunderstood.

We are happy to share our knowledge here

The burr, though unwanted, it is not possible to completely eliminate. Any machining or metal cutting process results in a burr. The amount of burr depends on the process, the tools used, resharpening frequency of the tools used and the material of the part. The amount of burr, burr position and the burr direction get defined with this.

Types of Machined burrs

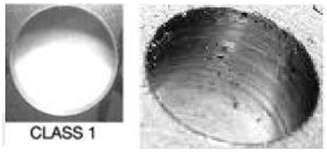

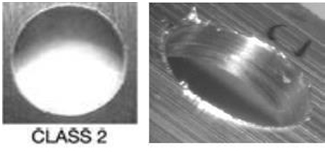

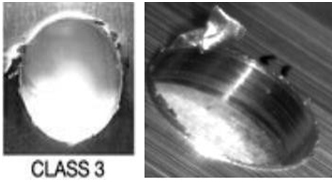

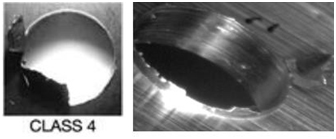

| Burr Class | Reference Image | Description |

| Class# 1 |  | Burrs are known as “micro burrs.” These burrs can only be seen with magnification and look like sharp edges to the naked eye. |

| Class# 2 |  | Burrs are also small burrs, sometimes called“feather burrs.” These burrs are able to be seen without magnification and can sometimes be scratched off of an edgeusing a fingernail. |

| Class#3 |  | Burrs are well attached burrs that are small in nature, but require significant, mechanical finishing force in order to be removed. |

| Class#4 |  | Burrs are well attached burrs that are large in nature, have significant route thickness and have a larger and stronger attachment point than Class 3 burrs. |

Why deburring –

- To avoid breakage – Excessive carburizing along the edges can often causebreakage when the parts are running

- To avoid damaging parts and bearings – If burrs are not removed, they may chip off during the running cycle and cause damage to the other parts and bearings.

- To avoid poor tool life in the finishing processes

- Removal of very sharp burrs reduces the risk of tool handlinginjuries

Burr Generation

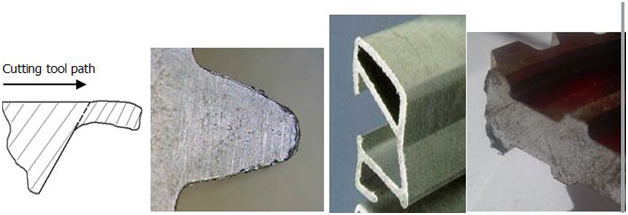

The Burr generation happens in metal cutting process which decides the burr position, amount & Direction of the burr…the cutting tool parameters & the direction of cutting plays an important role & need to be studied while deciding the Right Deburring Process.

We will talk about this in Part 2..please DO follow us..