NANOFINISH Machines

NANOFINISH technology consists of Superfinishing/ Microfinishing/ Lapping process for generating surface finish that can only be measured in Nanometers.

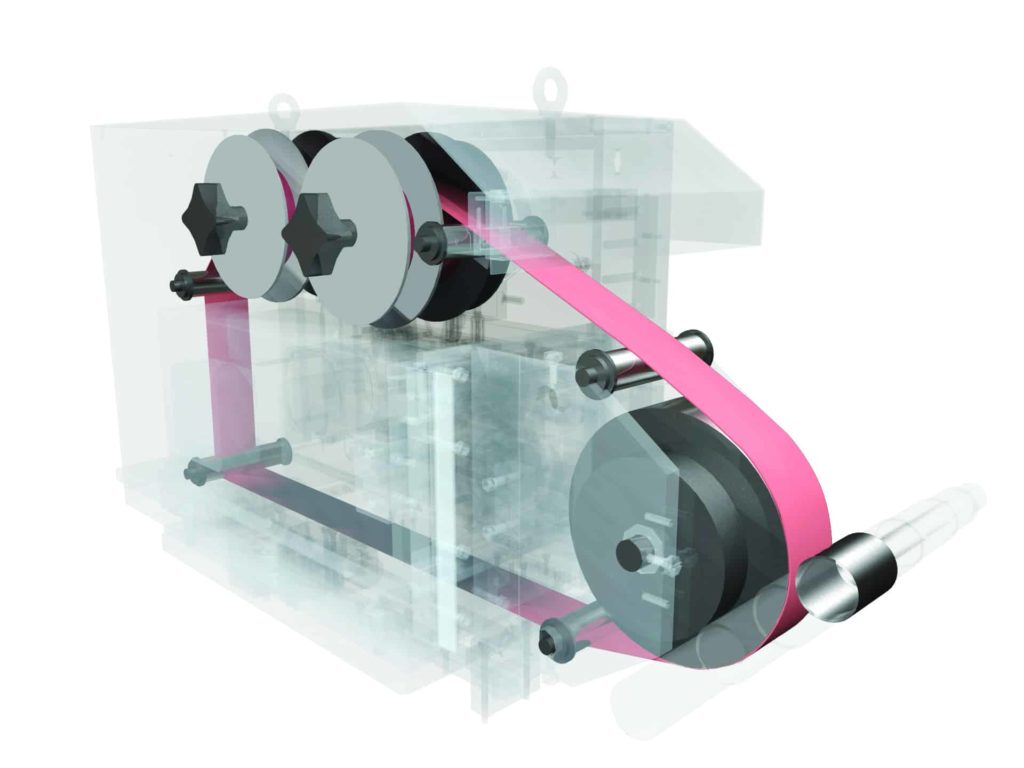

NANOFINISH range of machines use mainly Film Backed Abrasives with Grind Master NANOTouch Contact Tooling to provide reliable and high performance solutions to a wide variety of components ranging from Engine Parts to Rotogravure Cylinders. NANOFINISH Product Range makes use of Superfinishing & Microfinishing Technology

1. Superfinishing Technology:

It is line contact type method in which Film Backed Abrasives used with NANOTouch ROLL (Wheel) Backing is oscillated against the jobs which are either held between Centre or on Rollers (Centerless) provides surface finish improvement without damaging geometry, achieving Up to Ra 0.05

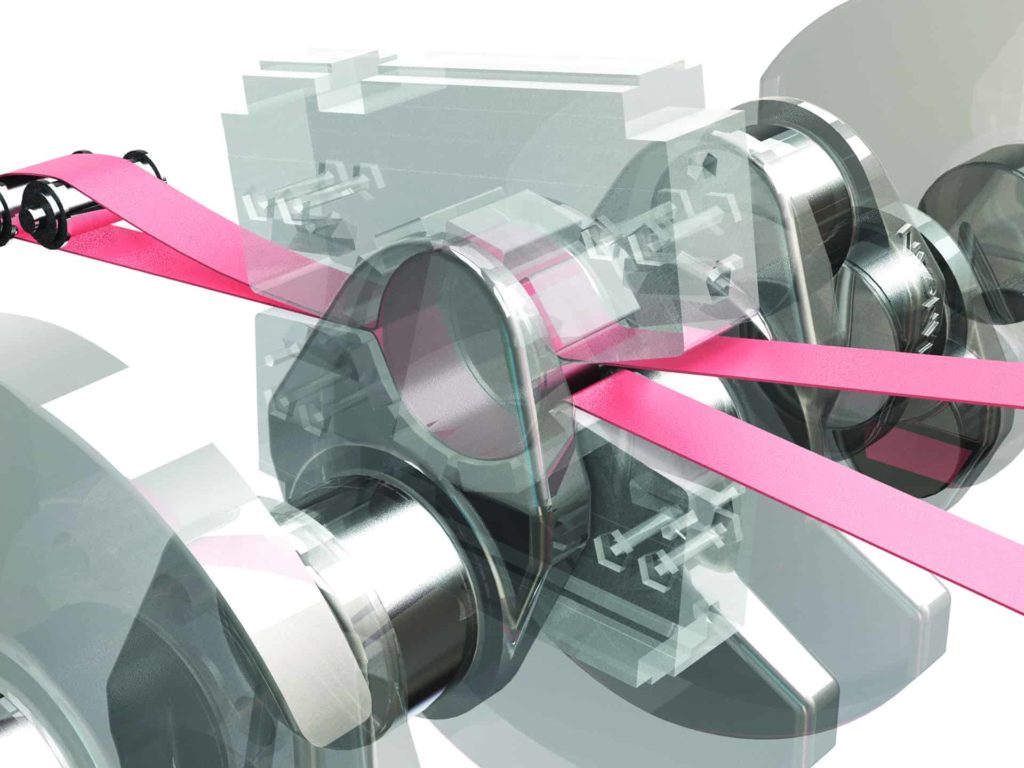

2. Microfinishing Technology:

It is surface contact type method in which Film Backed Abrasives are used with Various Contact Tooling such as NANOTouch STIFF (for Journals), NANOTouch FLEX (for Lobes), NANOTouch PLANAR

(For Faces).

In most cases the workpiece is oscillated between Centers. Apart from achieving Surface finish requirements, the process also achieves improvement in geometrical parameters such as roundness.

Customized Variations of NANOFINISH Technology such as GSF (Geometry – Size – Finish) are able to achieve multiple parameters in the same process with Advanced Size Control Technology.

ALL NANOFINISH Technologies ensure proper lubrication characteristics which results in extended products life along with elimination of noise & vibration.

NANOFINISH is a registered trademark of Grind Master.

Grind Master Expertise

- Over 500 successful Installations globally with more than 50% export.

- 15 Years of experience – Global Technology Leader in Specialized Machines

- 75 % Market Share in India

- Over Twenty Million Crankshafts Polished on Grind Master Machines – 25% of Chinese and 75% of Indian Market

- Global Technology Leaders with 20 Registered Designs, 20 Technology Patents (Pending) and 3 Trademarks

- Most Reliable Process Technology for NANOFINISH

Grind Master NANOFINISH Machines are based on a modular design concept, and can be optimized for specific applications with configurable stations including no. of arms, Arm positioning mechanisms and Automation Systems and Peripheral Systems. Optional additions include Deburring Units. The Machines are controlled with an Engineered Software – NANOFINISH Control System – built for finishing machines.

The state of the art range of machines NF Series are packed with several features that make them a market winner. Optimized Cycle times, Quick Setup Change, Quick Tooling Change, Ease of Maintenance are some of these.

NANOFINISH Applications:

- Superfinishing of Automotive Transmission Parts :

- Synchrocones, Loose Gears, Shafts and Transmission Yoke

- Superfinishing of Camshaft Journals

- Superfinishing of Piston Pins, Brake Pistons and Vacuum Pistons

- Superfinishing of Hydraulic Piston Rods

- Superfinishing of Gear Pump Shafts

- Superfinishing & Chrome Polishing of Rotogravure Cylinders

- Superfinishing of Steering Rack Bars

- Superfinishing of Flat surfaces of Gear Pump Shaft, Main Shaft, Balancer Shaft and Turbine Shaft

- Internal Superfinishing

- Centreless Throughfeed Superfinishing Machine (CST) for Automotive Pin type Components

- Superfinishing of Heavy Diesel Engine Pins

- Microfinishing of Crankshafts

- 200mm to 3.5 metres size

- Microfinishing of Camshafts

- 75mm to 2.5 metres size